"Excellence and Precision Since 1962"

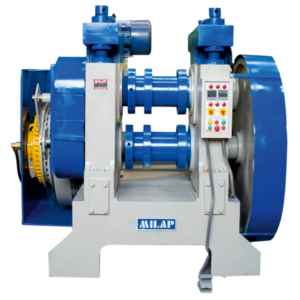

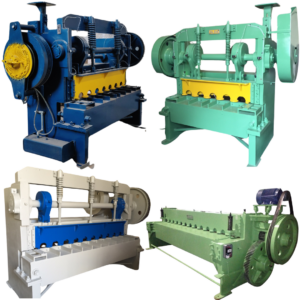

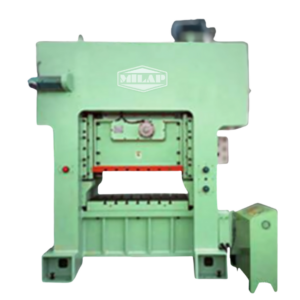

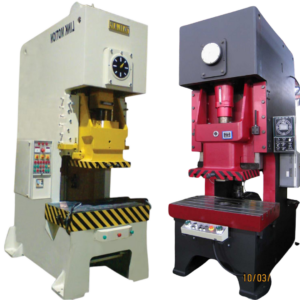

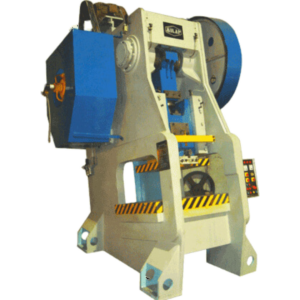

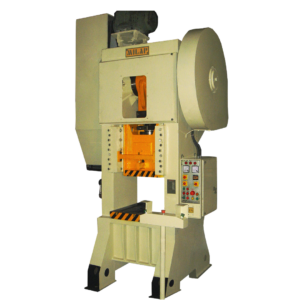

Crafting Power Press Machines for Timeless Performance.

At Milap Engineering Works, we engineer innovation, precision, and durability into every press machine, ensuring unmatched performance for decades to come.

"A Legacy of Trust, Precision, and Innovation Spanning Over Six Decades"

Honoring 62 Years of Excellence and Innovation in Power Press Machines

Since its establishment in 1961 by S. Mehar Singh, Milap Engineering Works has been dedicated to empowering the sheet metal components industry with cutting-edge solutions.

Founded with a vision of excellence, the legacy was carried forward by his sons, Mr. Amrik Singh and Mr. Tejinder Singh, who further expanded the company’s reputation for quality and innovation.

Today, the third generation—Mr. Kuljit Singh, Mr. Gurminder Singh, Mr. Karanveer Singh and Jaskaran Singh — leads the company into a new era, upholding its tradition of precision engineering and unparalleled customer service.

12800+

"Machines Delivered Across the Globe"

62+

Years of Trusted Industry Expertise

88,000 Sq. Ft.

Manufacturing Hub Built for Engineering Excellence in Ludhiana, Punjab

100%

Our Promise: Satisfaction Beyond Expectations.

Our Services – Redefined for Excellence

On-Site Machine Service & Maintenance

“Ensuring peak performance, right at your facility. Our expert technicians deliver timely maintenance and repairs to keep your operations running smoothly.”

Dedicated Technical Support

“Round-the-clock assistance for seamless operations. From troubleshooting to optimization, our technical team is just a call away.”

Precision Machining Solutions

“Crafting perfection with state-of-the-art machining. We deliver high-precision components tailored to your industry needs.”

Genuine Spares & Replacement Parts

“Original spares designed for longevity and performance. Keep your machines running like new with our authentic replacement parts.”

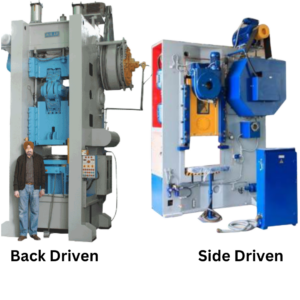

Custom-Built Power Press Solutions

“Tailored to your unique requirements. From design to delivery, we create power press machines that fit your exact needs.”

Expert Consultancy for Power Press Solutions

“Unlock the full potential of your operations. Our consultancy services provide actionable insights for efficiency, safety, and growth.”

Milap at Global Exhibitions

"Meet the Leaders Shaping the Future of Power Press Technology"

"The Force Behind Our Global Success"

CEO

KULJIT SINGH

CMO

Gurminder Singh

CFO

Karanvir Singh

CPO

Jaskaran Singh

Milap News & Insights

“Precision Engineering, Delivered to Your Doorstep”

Why Choose Us? – Precision You Can Rely On. “In the world of power press…

“Your Success is Our Mission”

“At Milap Engineering Works, we don’t just build machines—we build relationships. Here’s why we’re the…

“Why Milap Engineering Works? Because Legacy Matters”

Why Choose Us? – 62 Years of Trust and Innovation “With over 62 years of…